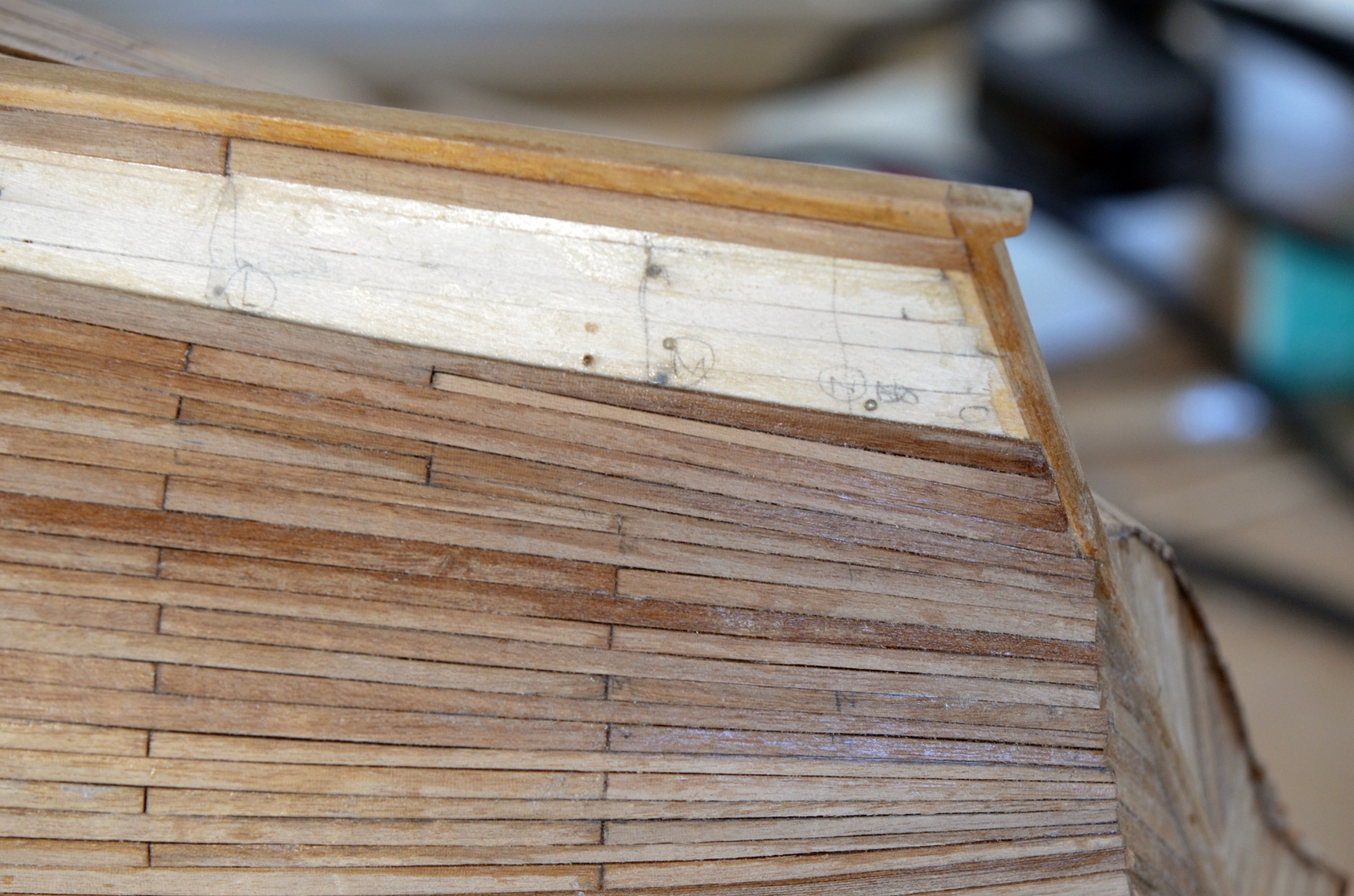

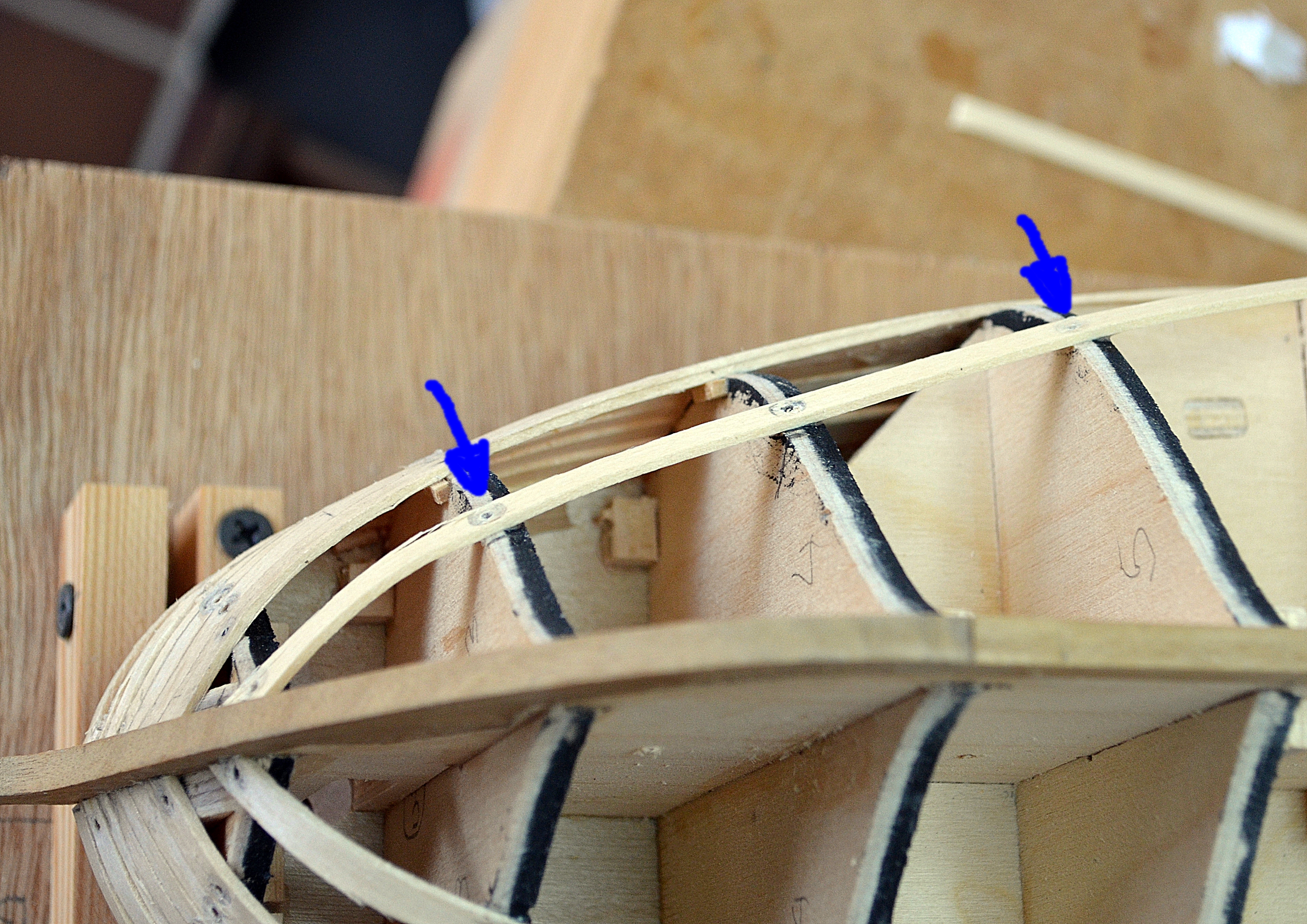

The first run of planks in lime have been completed on each side. There will be some filling and sanding needed to get all the curves of the hull running smoothly, but I’ll probably leave that until I’ve completed all the first layer. Mostly there have been no problems, and my plank bending skills have improved. I did have a small problem when fitting one of the final planks, between two that had already been fitted, in that the glued joint of the plank to the bulkhead de-laminated. I hope I’ve cured this by drilling tooth-pick sized holes in the offending plank, into the bulkhead, and those either side, then reinforcing the joint with glued toothpicks (see photo). After sanding down, it seems to have worked.

I’ve found a useful hull planking instruction manual, written by J. Hatch (Captain Pugwash) on the internet:

Click to access plankingprojectbeginners.pdf

I wish I’d read this before starting the kit, and I would recommend it to any beginner before diving in to an ambitious model boat project that involves planking a hull. There is some detail on how to cut ‘RABBET LINES’. These are grooves in the keel that accept the plank ends for a neater finish. In the case of this kit, it might have been better to cut some of these before gluing the keel together. Too late now, but I’m still confident I can achieve a good result.

My next planking will be five of six plank widths lower down. Once again, I will glue one plank in place, letting it run the way it naturally wants to run to the bow and stern, then I will complete planking in between. As before, I will replicate each plank on one side, with the same on the other side.